Electronic Technology Industry

Electronic gas: a key "blood" in the field of electronic technology. In the semiconductor industry, electronic gas plays a crucial role as one of the core raw materials in the manufacturing process. It runs through the entire process of chip manufacturing, from raw material preparation to finished product output, all of which rely on the support of electronic gas.

◎ Application in Chip Manufacturing →

◎ Key Technologies and Challenges →

◎ The Future Trend of The Gas Industry in the Field of Electronic Technology →

GUIDA GAS

Application in Chip Manufacturing

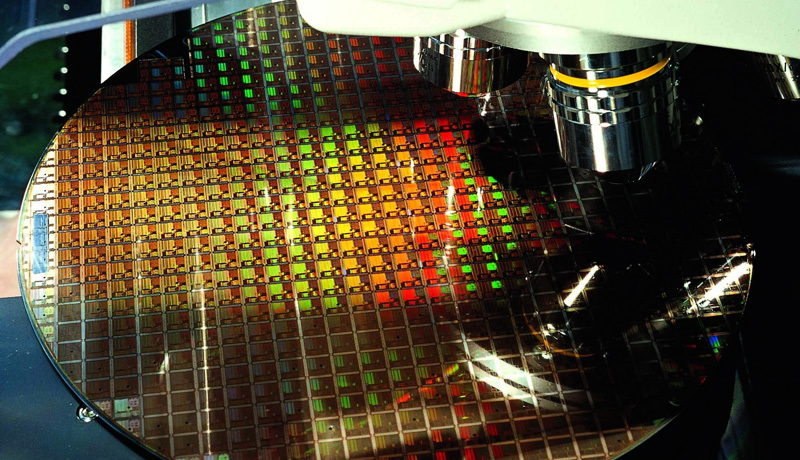

Deposition process: During the deposition process, gases such as silane and ammonia are required to form a thin film. These gases deposit one or more thin films on the surface of the chip through chemical reactions, laying the foundation for subsequent process steps.

Lithography process: Lithography is one of the key steps in chip manufacturing, which requires the use of specific gases such as argon fluoride for precise lithography. These gases interact with light sources such as lasers or ultraviolet rays, causing chemical reactions on the thin films on the chip surface, thereby forming the desired circuit patterns.

Etching process: Etching is the process of removing unwanted parts of the chip surface to form circuits. During this process, gases such as chlorine and nitrogen trifluoride play a crucial role. They undergo chemical reactions with the materials on the surface of the chip, removing unnecessary parts and leaving precise circuit patterns.

Doping and Annealing: Doping is the process of introducing other elements into a chip to alter its electrical properties. During this process, gases such as phosphine may need to be used. Annealing is to eliminate defects and stresses generated during the doping process, and improve the reliability and stability of the chip.

Cleaning and passivation: At various stages of chip manufacturing, chips need to be cleaned to remove impurities and contaminants. In addition, it is necessary to form a protective film on the surface of the chip to prevent oxidation or corrosion. These processes may require the use of gases such as nitrogen and hydrogen.

Key Technologies and Challenges

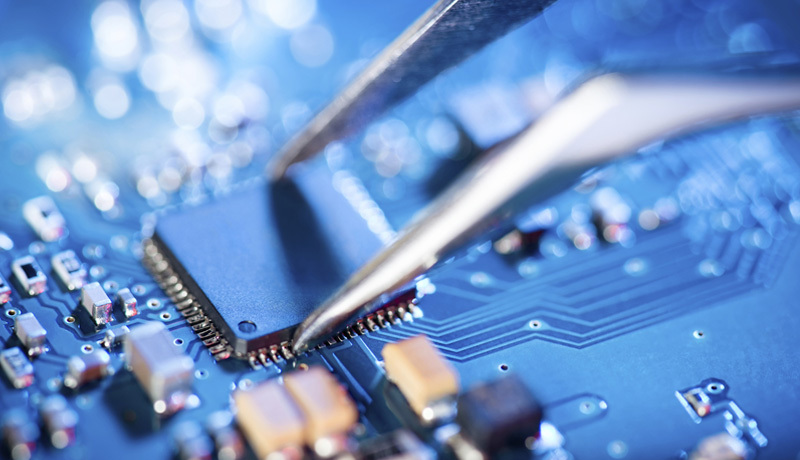

Accurate control of gas: In the chip manufacturing process, it is necessary to precisely control parameters such as gas flow rate, pressure, and temperature. This requires the gas industry to have high-precision control technology and equipment.

Safe storage and transportation of gases: Many gases used in chip manufacturing are toxic or corrosive, so their storage and transportation processes require strict adherence to safety regulations. The gas industry needs to ensure the safe storage and transportation of these gases to prevent leaks or accidents.

The Future Trend of The Gas Industry in the Field of Electronic Technology

Green production: With the increasing awareness of environmental protection, the gas industry will pay more attention to green production. By improving production processes and increasing resource utilization, the impact on the environment can be reduced.

Technological innovation and research and development: In order to meet the high requirements of chip manufacturing for gases, the gas industry will continue to increase its efforts in technological innovation and research and development. By developing new gas preparation technologies and improving gas purity and stability, we aim to provide higher quality gas products and services for chip manufacturing.

International cooperation and development: With the deepening of globalization, the gas industry will strengthen cooperation and communication with the international market. By introducing advanced technology and equipment, and participating in international competition, we aim to promote the rapid development of the gas industry in the field of electronic technology.

The application of electronic gases in the field of electronic technology is crucial. It not only provides necessary reaction media and precise control of the production process for chip manufacturing, but also ensures production safety and environmental protection. With the continuous development of the semiconductor industry, the gas industry will continue to play a more important role in the field of electronic technology.